Invention

Eberhard Schöck (1935-2022) was considered a visionary. With his solution for minimising thermal bridges on cantilevered structural components, he revolutionised the building industry and set new standards.

plusThe invention of the Schöck Isokorb® was one of the most important milestones in the history of our company. It is as innovative today as it was then and exemplifies the standards we set for the development of our entire product range: forward-looking construction, better environmental compatibility, more safety, simple handling and the resulting economic efficiency.

Eberhard Schöck (1935-2022) was considered a visionary. With his solution for minimising thermal bridges on cantilevered structural components, he revolutionised the building industry and set new standards.

plusIt was a skiing holiday in 1979 that led to the birth of the Isokorb®: While in his vacation home, Eberhard Schöck discovered widespread mould formation on the ceiling, which was adjacent to numerous uninsulated exterior balconies. While still on holiday, he explored his first ideas and prepared sketches looking for a solution to overcome this weakness in buildings.

The very next year, Eberhard Schöck applied for his first patent for this revolutionary idea. In 1983, the Isokorb® Type M “insulation element for cantilevered balconies” was presented for the first time at the DEUBAU trade fair in Essen and at the SWISSBAU in Basel. It was launched on the market that same year.

Eberhard Schöck looked back fondly on that moment: “The interest in this product from the trade was huge, so we hoped we had a product with a future here.” He was proven right, even to this day, 40 years later.

With his invention for minimising thermal bridges on cantilevered structural components, Eberhard Schöck revolutionised the building industry in 1983 and was ahead of his time:

Schöck Isokorb® set new standards both then and now. Eberhard Schöck’s vision of “making building easier” is embedded in the Schöck DNA. Thanks to continuous further development, Isokorb® is still a state-of-the-art solution – even today – when it comes to the simple, energy-efficient and safe connection of cantilevered structural components, such as balconies, to buildings.

Schöck Isokorb®, the innovative thermal insulation element, gradually established itself on the market from 1983 onwards. Over the years, further product innovations followed and many new markets were opened up.

plusFollowing the revolutionary invention of Isokorb®, its many strengths became evident. The innovative solution attracted attention and was well received by the market. In order to meet the high demand for Isokorb®, Schöck expanded its production facilities and hired technical advisors to provide excellent service to those involved in construction.

Outside Germany, too, the markets quickly recognised that Schöck Isokorb® now offered an intelligent and effective solution for minimising thermal bridges. The first orders were received from the present-day markets of the Czech Republic, Poland, Italy and Scandinavia. Today, Isokorb® is sold in approximately 40 countries.

»You should never rest on your laurels. If you want to be successful you have to develop completely new things or improve existing things.«

(Eberhard Schöck)

This was Eberhard Schöck’s motto and it still holds true today. Even 40 years later, there is no end to the new innovations. On the contrary – it is an incentive for all employees to continue writing the success story.

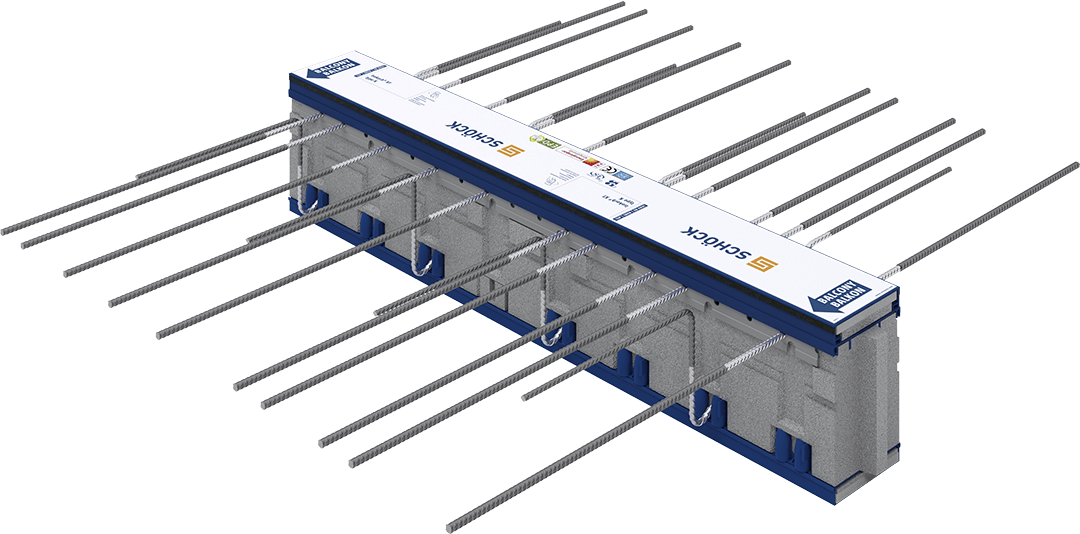

Schöck Isokorb®, the innovative and simple thermal break solution for minimising thermal bridges has become indispensable in the construction industry. Not only can it be used in a variety of ways, but it also has all the relevant building authority documents.

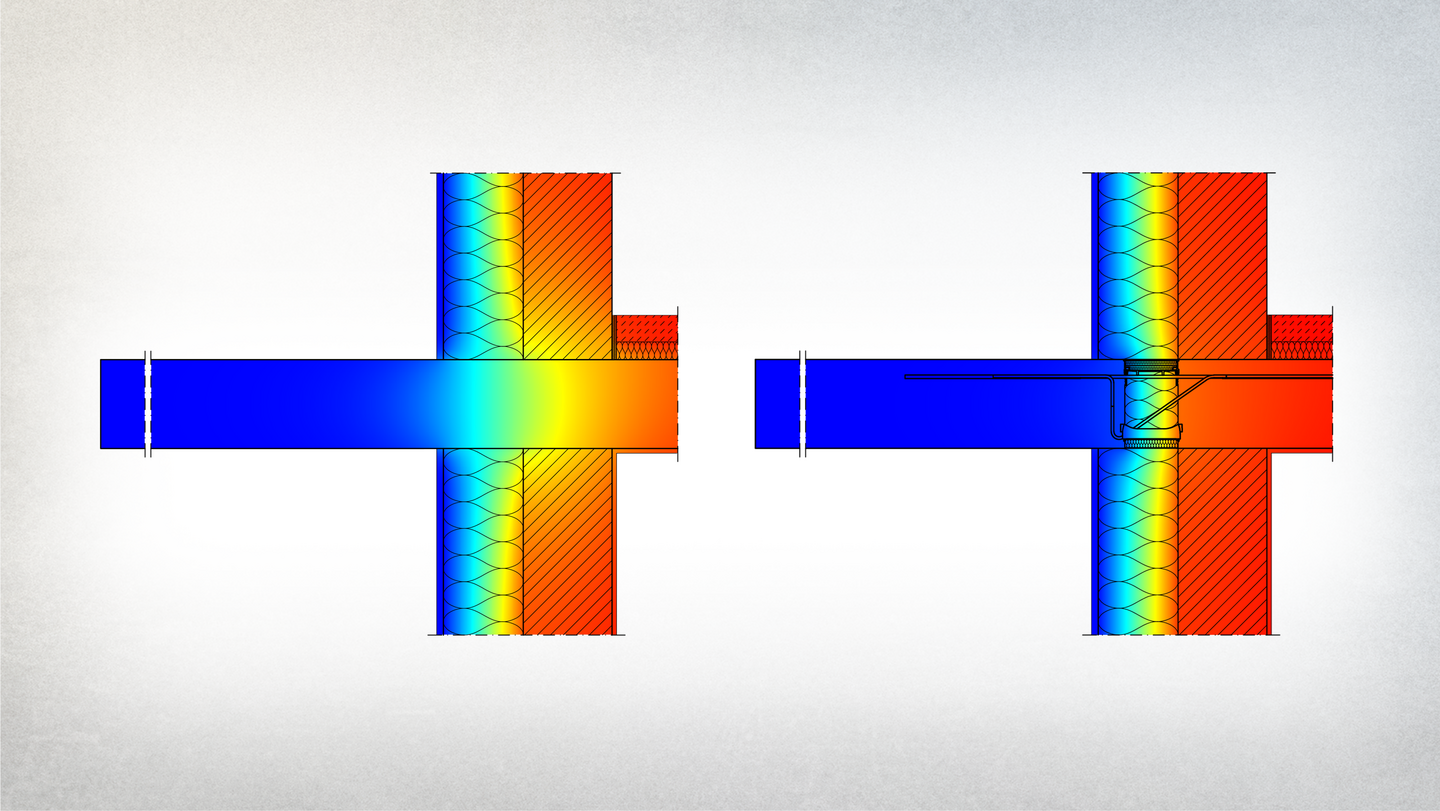

plusEnergy loss occurs when structural components that penetrate the building envelope provide a pathway that allows heat to more easily pass through and escape to the outside. These areas are known as thermal bridges. In addition to the energy loss that occurs with thermal bridging, structural damage often occurs due to the formation of condensation and mould. The heat loss can be prevented by ensuring continuous thermal insulation at the building envelope. Load-bearing thermal insulation modules such as Schöck Isokorb® are an ideal solution, providing not only thermal insulation, but also structural integrity.

The applications covered by the Schöck Isokorb® product range are very diverse, offering solutions to prevent thermal bridging at cantilevered or supported balconies, loggias, arcades, canopies and parapets. It includes solutions for concrete-to-concrete, concrete-to-steel and steel-to-steel connections, in both new buildings and retrofits.

Beyond the typical applications, Schöck Isokorb® makes unique and challenging installations possible, such as unusual geometries, large cantilever lengths or the construction of timber hybrid buildings.

Let’s take a look together at the changes that have taken place over the years.

plusSupporting information is indispensable when introducing a new product. Eberhard Schöck knew this even back in 1983 when the Schöck Isokorb® was launched. The information folder at the time contained all the knowledge about the “balcony insulation board with reinforcement” or the new and innovative thermal insulation element: product information, technical drawings, installation instructions and test reports.

The information folder from 1983 still exists today – but a lot has happened in the meantime. With the expansion of the product range, it became necessary to create additional technical information sheets for the different connections and construction types. Naturally, the overall appearance of this information has also changed over the years. What remains the same is the detailed technical information that serves to assist the planner.

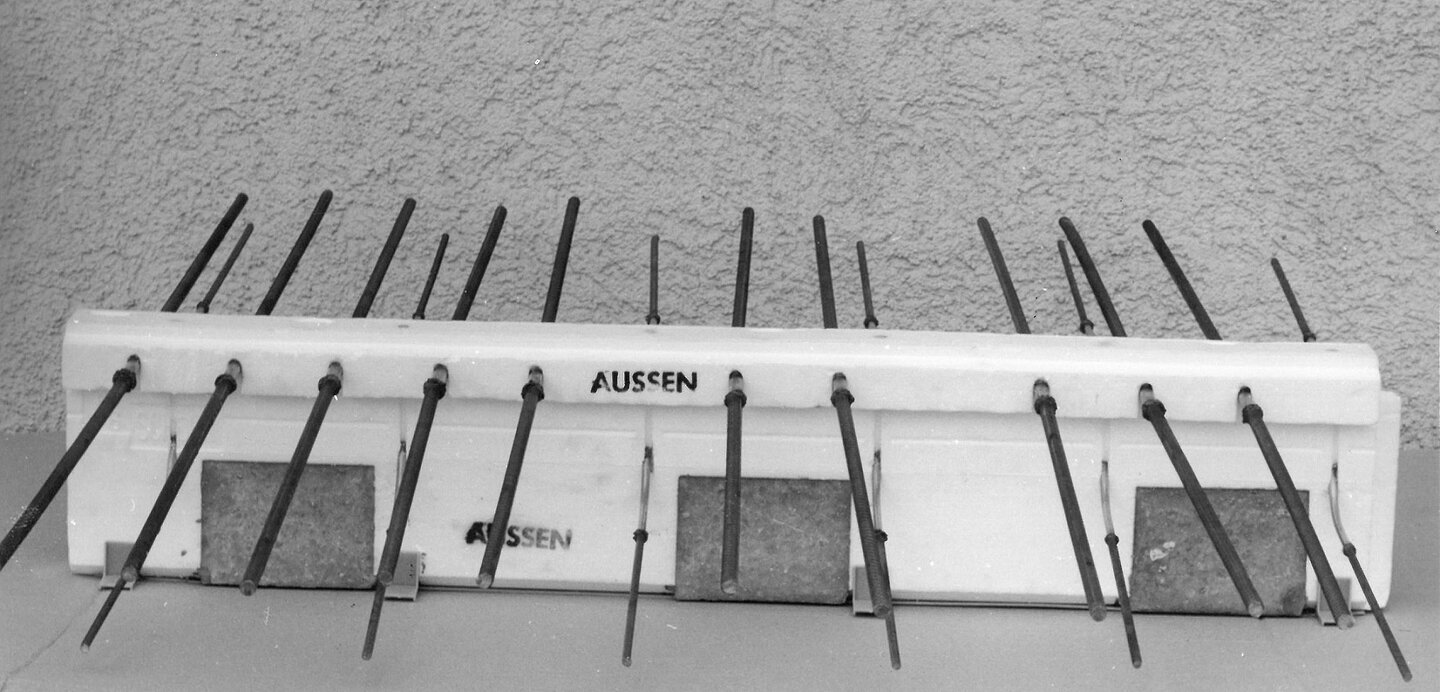

The thrust bearing, an important part of the Isokorb®, was made entirely of stainless steel back in 1987. Smooth steel was used in the joint and welded steel plates were used to transfer the compressive forces into the concrete structural component. Due to its appearance, it was affectionately referred to in-house as the “bone”.

The original stainless steel thrust bearing was replaced over the years by an innovative thrust bearing filled with high-performance fine concrete. As a result, the heat transmission is reduced by an average of 24%. Thanks to the geometry of the thrust bearing, Schöck Isokorb® is even easier to install.

An Isokorb® produced in 1997 involved a great deal of manual work…

…and that is still the case even today during assembly of the wide range of different Isokorb® types. But digitalisation has also become an integral part of production – manufacturing is now completely paperless and production plans are displayed on monitors. Production of the necessary individual components for Schöck Isokorb® is fully automated for the most part.

The advertising was showy and unrefined to draw attention to itself and to the innovative thermal insulation element.

Over the years, the Schöck Isokorb® brand has been refined. Today, the marketing is more polished and professionally presented, reflecting a more sophisticated product and business approach.

Schöck Isokorb® has continued to develop since 1983. In close cooperation with partners and customers, we are constantly working on new ideas and innovations to make building even easier.

plusThat is why all the employees continually strive to make Schöck Isokorb® even better and more innovative in the future. In doing so, it is important for us not only to further develop the product and its components, but also to take the market requirements into consideration. The broad Schöck Isokorb® portfolio therefore also offers solutions for the growing demands. The large variety of types in the Isokorb® product family gives architects and planners more design freedom when carrying out their projects.

All product innovations are subject to an intensive development period before they are used in international projects. But the best argument comes from practice.

plusThe advantages and benefits of the Isokorb® product family are impressive, not only in theory, but also in practice. We see this with the numerous architecturally and technically sophisticated reference projects that rely on Isokorb’s thermal insulation. These buildings demand the highest standards in architecture and energy efficiency to create an optimal end result – these projects are an ongoing source of inspiration and pride for us at Schöck.